Arikeh Pardaz Engineering Company (APEC Ltd.) was founded in 2008 to address the lack of a systematic, project-oriented regulatory framework in mega projects.

APEC is a leading engineering company which starts deep studies in each and every activity from the start of engineering up to end of commissioning in mega projects to reduce the total cost of execution.

These studies lead to the development of optimal procedures and customized software tailored for various types of contracts in the following projects:

- Oil & Gas Refinery plants

- Petrochemical plants

- Power plants

- Steel Making plants

- High-tech Manufactories

Our primary goal is to implement a systematic approach to managing critical aspects of industrial projects, ensuring time savings and cost minimization for our clients.

Study & Analyze

We believe that the first step in operating a mechanism is to study and analyze it in detail. This ensures a clear understanding of its inputs, outputs, relationships, and goals.

Define

We aim to define a system that addresses all the requirements of the mechanism. This system must encompass clearly defined goals, working procedures, distinct responsibilities and authorities, specialized software, manpower charts, and detailed job descriptions.

Run

After creating the system, the next step is to implement it. The more critical phase is to closely monitor the performance of the operational system and gather sufficient feedback from operators, customers, and clients.

Improve

Enhance the implemented system by addressing weaknesses, reinforcing its strengths, and aligning it seamlessly with the evolving requirements.

Clients

We are proud to have such valuable customers

Services

the more experiences we got, the more valuable services we are providing, Ask our happy clients!

3D Modeling

We provide precise, multidisciplinary 3D plant modeling services using Plant 3D and PDMS. We specialize in transforming 2D designs into immersive 3D models, offering EPCs, consultancies, and OEMs accurate visualizations of facilities to enhance efficiency and streamline construction.

Material Management

We use our Turboware system to manage material flow in the most efficient way possible.

Our extensive manpower and robust system empower us to be the leading project warehouse operator.

Engineering Management

We worked diligently to identify engineering bottlenecks and find the best solutions to address them.

You will never face claims; we know exactly how to manage your counterparts.

Construction

"We have extensive experience in piping, mechanical, and electrical fabrication and installation.

APEC has grown alongside Iran's resource industry since 2008. We have contributed to the construction of key segments in some of Iran's largest resource and infrastructure projects and are well-positioned to support the evolving construction needs of the future.

We are accustomed to operating in challenging terrains, a reality that is unlikely to change. The nature of oil and natural gas often places projects in harsh regions, all of which present unique challenges. These are challenges we are fully prepared to face in order to help our clients achieve success.

Plant 3D and PDMS Modeling Services

At Apec, we deliver comprehensive, multidisciplinary plant modeling services designed to meet the evolving needs of EPC companies, engineering consultancies, and OEMs. Our skilled professionals specialize in Plant 3D and PDMS platforms, offering advanced 3D modeling solutions that optimize designs and reduce risks.

With extensive on-site expertise, we create highly accurate digital models, enabling clients to visualize and navigate their facilities before construction begins.

Our Service Offerings

Efficient management of database-driven workflows for seamless project execution. Customizing projects to match client-specific requirements, including piping catalogs and specifications. Preparing mechanical data sheets and equipment layouts. Collaborating with vendors for seamless data integration. 3D modeling of key structural elements, including: Equipment foundations Platforms, walkways, ladders, and handrails Pipe racks, skid base-frames, lifting lugs, and anchor bolts Converting 2D CAD drawings into precise 3D models. Modeling piping systems and supports based on general arrangement (GA) drawings. Designing physical supports using advanced 3D tools and adhering to client standards. 3D modeling of instruments, junction boxes, and cable trays aligned with electrical and instrumentation layouts. Integrating designs across disciplines to enable the extraction of:

Equipment layouts and general arrangement drawings

Piping isometrics and nozzle orientation diagrams

Fabrication drawings

Material take-off (MTO) and Bill of Materials (BOM) Our expertise ensures precision, collaboration, and efficiency, enabling clients to streamline workflows and achieve superior project outcomes. Let Apec transform your vision into reality with cutting-edge 3D modeling solutions.

Material Management and Warehousing

More than half of the expenditures in oil, gas, petrochemical, and power plants are typically attributed to materials, underscoring the critical importance of effective material management and warehousing during construction. Delays, duplicate purchases, damaged materials, lack of necessary information, errors in installation, and other common issues in construction projects often lead to owner complaints. These challenges have driven us to place the warehousing system at the core of our focus.

For Owners

These types of contracts are when owner have several construction contractors and intends to manage the warehouse and materials by itself and he just delivers the materials when construction contractors request the materials. For these types of contracts following services will be provided:

For Contractors and Sub Contractors

These types of contracts are when construction contractor manages the materials and project warehouses at his cost. Here he will be responsible about materials at their arrival at site. For these types of contracts following services will be provided:

Engineering and Site Technical Offices Management

If we call the project warehouses as the heart and blood circulation system of the construction projects, technical offices will act as the brain of a construction project. Technical office which generates technical information and conducts the construction, when is linked to material department, it will provide the most efficient conditions for both contractors and owners. We can serve as technical office contractor besides the project warehousing for owners or construction contractors

For Owners

These types of contracts are when owner have several construction contractors and intends to manage the warehouse and materials by itself and he just delivers the materials when construction contractors request the materials. For these types of contracts following services will be provided:

For Contractors and Sub Contractors

These types of contracts are when construction contractor manages the materials and project warehouses at his cost. Here he will be responsible about materials at their arrival at site. For these types of contracts following services will be provided:

Our Selected Gallery of Projects

Some of our finished and on-going Projects

Arya Sasol Polymer Co.

Service 1:

Material Management and Warehousing

Service 2:

Engineering Management and Site Technical Offices

Project:

C2 Cracker & Offsite

Client:

Arya Sasol Polymer Co.

Location:Asalooyeh

Technip-Nargan J.V.

Service 1:

Material Management

Project:

LDPE Plant

Client:

Technip-Nargan J.V.

Location:

Asalooyeh

Hormozgan Steel Complex

Service 1:

Material Management and Warehousing

Service 2:

Engineering Management and Site Technical Offices

Service 3:

QC and WJCS(Welding Joint Control System)

Project:

Steel Making Plant

Client:

IRITEC - Pamicco

Location:

Bandar Abbas

South Pars Gas Development Phases 15&16

Service 1:

Material Management and Warehousing

Service 2:

Engineering Management and Site Technical Offices

Service 3:

QC and WJCS(Welding Joint Control System)

Project:

South Pars Gas Development Phases 15&16

Client:

Sepanir-Arya Naft Shahab

Location:

Asalouyeh

Shiraz 3rd Urea and Ammonia Development Plant

Service 1:

Material Management and Warehousing

Project:

Urea and Ammonia Plant

Client:

PIDEC

Location:

Shiraz

Mahabad Petrochemical Co.

Service 1:

Material Management and Warehousing

Project:

HDPE, LLDPE, BUTENE1 Plant

Client:

Mahabad Petrochemical Co.

Location:

Mahabad

South Pars Gas Development Phases 22,23&24

Service 1:

Material Management

Project:

South Pars Gas Development Phases 22,23&24

Client:

Payandan Co.

Location:

Asalouyeh

South Pars Gas Development Phases 17&18

Service 1:

Engineering Management and Site Technical Offices

Project:

South Pars Gas Development Phases 17&18

Client:

IPMI Co.

Location:

Asalouyeh

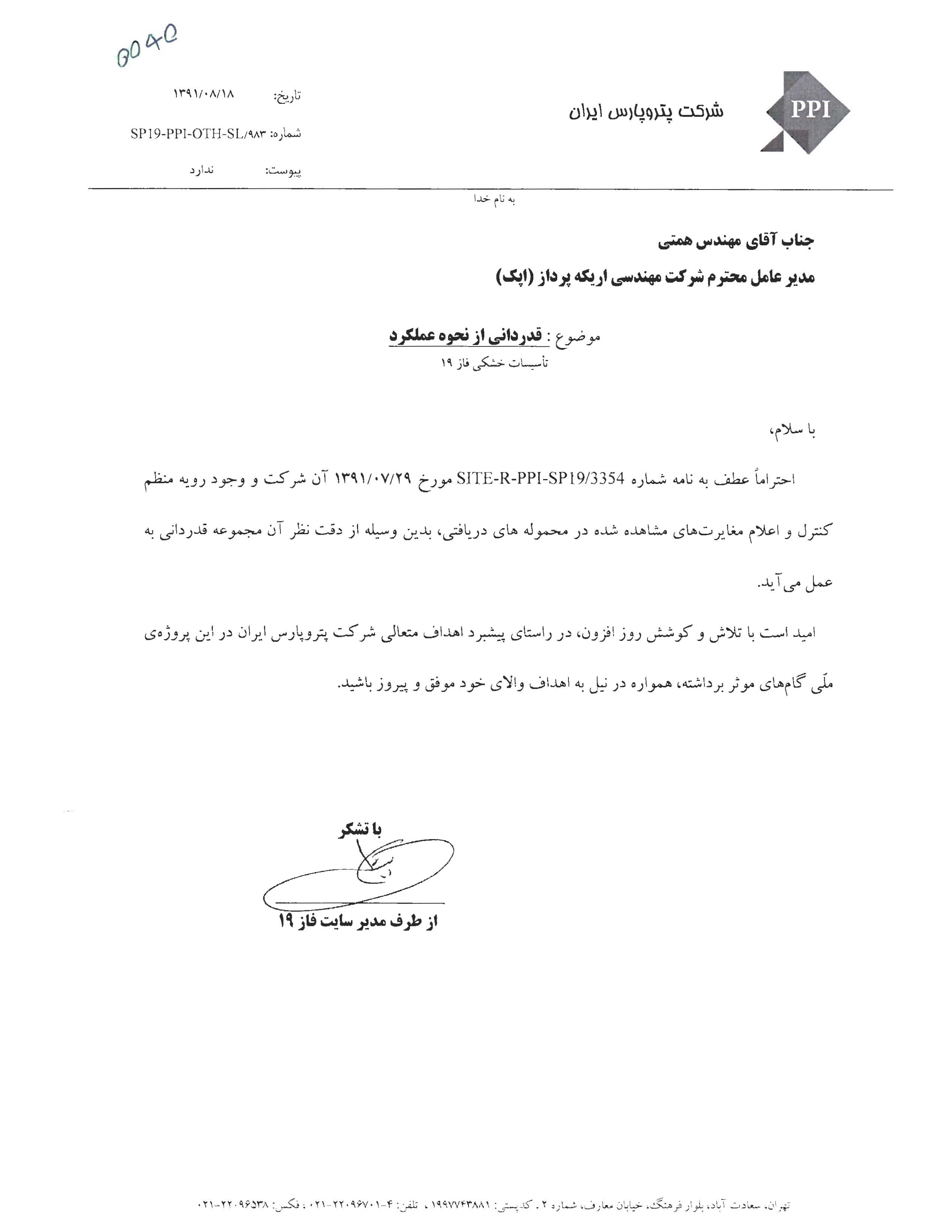

South Pars Gas Development Phases 19

Service 1:

Material Management and Warehousing

Service 2:

Engineering Management and Site Technical Offices

Project:

South Pars Gas Development Phases 19

Client:

Petro Pars Iran Co.

Location:

Asalouyeh

South Pars Gas Development Phases 19

Service 1:

Material Management

Service 2:

Engineering Management and Site Technical Offices

Project:

South Pars Gas Development Phases 19

Client:

Boland Tabaghe Co.

Location:

Asalouyeh

Ilam Petrochemical Co.

Service 1:

Material Management and Warehousing

Service 2:

Engineering Management and Site Technical Offices

Project:

Olefin and Offsite

Client:

Ilam Petrochemical Co.

Location:

Ilam

Veniran Apadana Petrochemical Co.

Service 1:

Material Management

Service 2:

Engineering Management and Site Technical Offices

Project:

Methanol Plant

Client:

Apadana Petrochemical Co.

Location:

Asalouyeh

Asalouyeh Green Tanks Petrochemical Co.

Service 1:

Material Management and Warehousing

Service 2:

Engineering Management and Site Technical Offices

Project:

Tank Farm

Client:

Asalouyeh Green Tanks Petrochemical Co.

Location:

Asalouyeh

Alborz Turbine Co.

Service 1:

Procurement

Project:

Supply of GE F5 Turbine sub assembly and parts

Client:

Alborz Turbine Co.

Location:

Asalouyeh

South Kaveh Steel Complex

Service 1:

Construction

Project:

Piping, Mechanical and Electrical Installation for RO Plants

Client:

Melli Sakhteman Co.

Location:

Bandar Abbas

South Kaveh Steel Complex

Service 1:

Construction

Project:

UG Piping for whole complex

Client:

Melli Sakhteman Co.

Location:

Bandar Abbas

Hormozgan Steel Complex

Service 1:

Construction

Project:

Piping, Mechanical and Electrical Installation for Oxygen Plant

Client:

Pammico Co.

Location:

Bandar Abbas

Hormozgan Steel Complex

Service 1:

Construction

Project:

Piping, Mechanical and Electrical Installation for PRS Plant

Client:

Pammico Co.

Location:

Bandar Abbas

Mapna Turbine Hightech Manufactury

Service 1:

Construction

Project:

Onboard Piping and tubing and Mechanical Installation for Turbine and Compressors

Client:

Mapna Turbine TUGA Co.

Location:

Fardis Karaj

Boland Tabagheh Co.

Service 1:

Construction

Project:

Field Piping Fabrication and Spool Installation for Units 108, 147, 148 Phase 19 PSEEZ

Client:

Boland Tabagheh Co.

Location:

Asalouyeh

Petro Pars ltd.

Service 1:

Construction

Project:

Hot and Cold Insulation Installation for Units 108, 147, 148 Phase 19 PSEEZ

Client:

Boland Tabagheh Co.

Location:

Asalouyeh

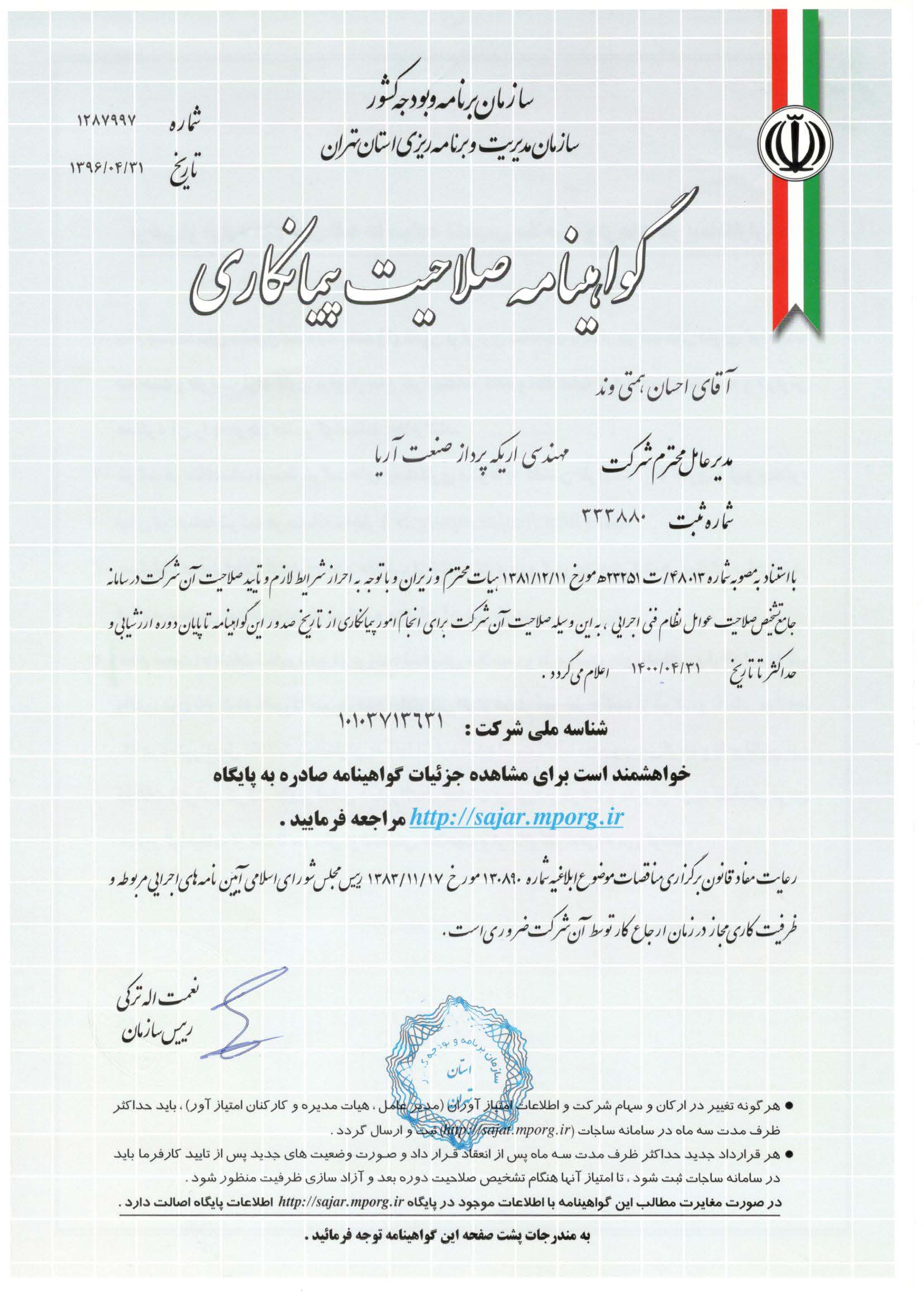

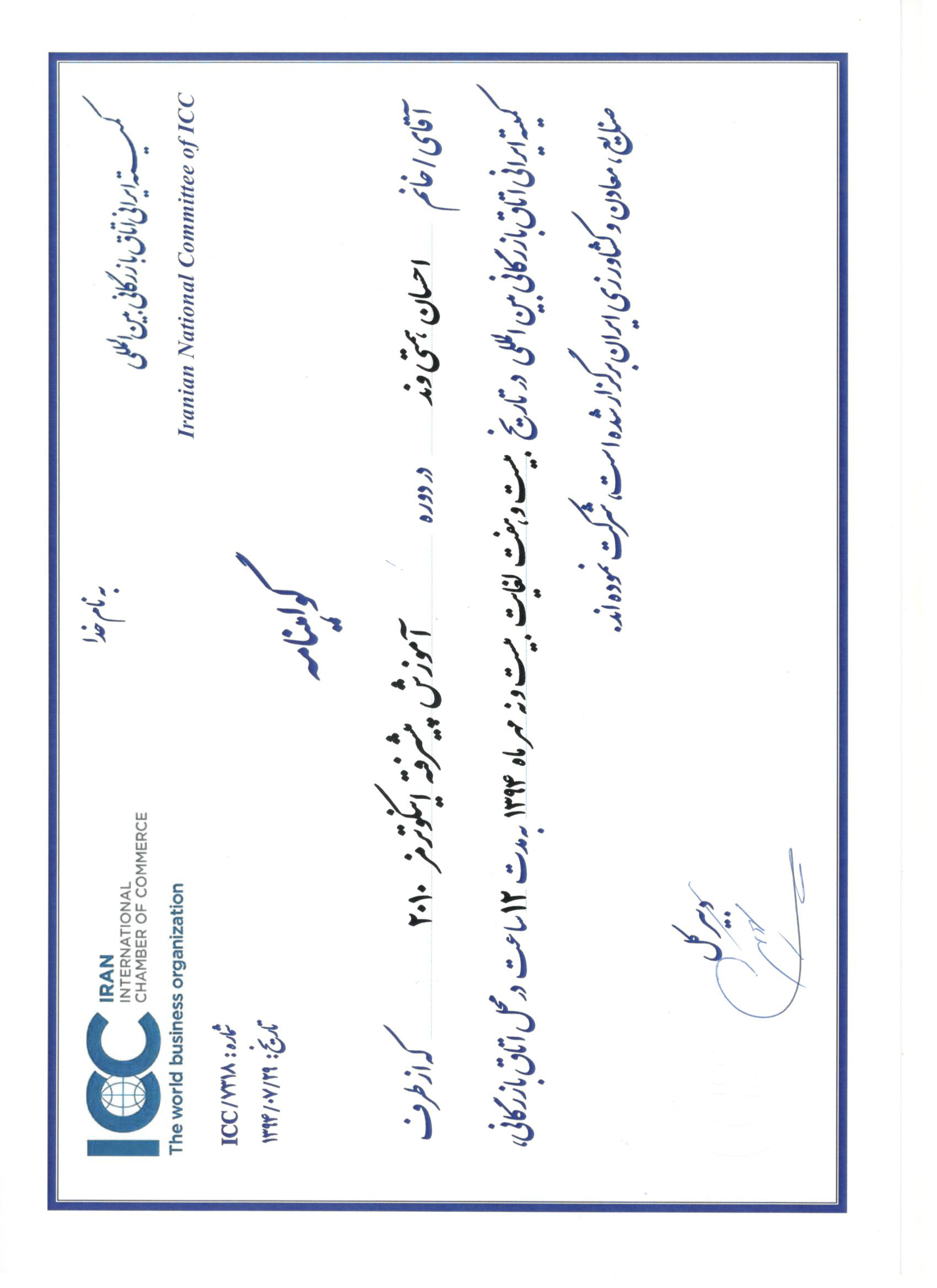

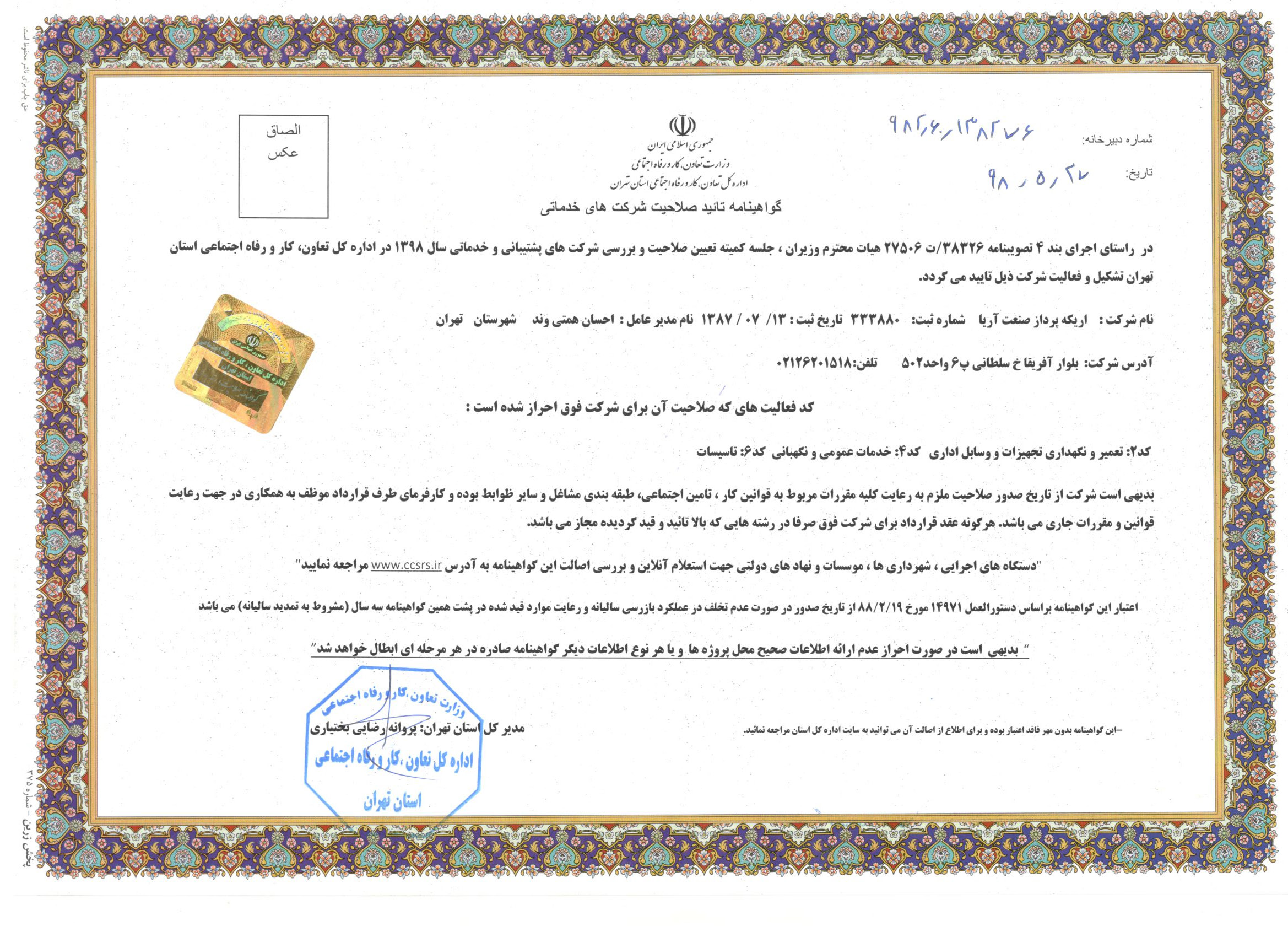

Achivements

Some of achivements listed below:

- All

- Authorizations

- Construction

- Material Management

- Engineering Management

Turboware

A Comprehensive Material & Piping Management System

|

|

Objectives

Design, implementation and run a comprehensive material and technical offices management system which includes software, experienced human resources, procedures, relations, authorities and responsibilities to meet the requirements of our owners in minimum costs and times.

MRS Release

MRS (Material Receipt Sheet) formats will be generated for each consignment just after warehouse approves the receipt of consignments. Any discrepancy between the claimed packing lists of the vendors and received physical materials will be considered in MRS to avoid any loss for owners.

Warehouse Adjutancy

MIV documents will be always equipped with a summary format which provide information about Location, Package No., Color Code, Warehouse Inventory, Pipe Length, Batch No.,etc. of the requested materials in MIV which facilitate the material delivery for warehouse.

Define The Access Level

It is very critical to limit the accessibility of the users according to their job specifications to prevent job interferences. A simple example is the accessibilities of the warehouse users which are completely distinct from the accessibilities of the technical offices users.

Search Through items and drawings

User Friendly System

As wide numbers of people will be the users of the software, it has been designed user friendly and can be trained within minutes.

Material Traceability

When procedures have any obligations about material matching with vendor certificates, system will not allow to deliver materials until necessary documentations have performed.

General Reports

Different types of reports related to material or technical fields can be generated by the system. These reports usually are modified in each project according to the tastes of the users.

Material Reconciliation Reports

Material Reconciliation Status of each contractor can be reported by the system at any period of the project.

Surf through Joint History

Data Provision

Following information will be accessible from Turboware software: 1- Detailed data of received materials including: Purchase Order No., Packing List No., Packages No., Tag, Description, Qty, Batch No., Unit Weight, Net and Gross Weight of Consignment, Consignment Dimension, Consignment Volume, Date of Receipt, OPI Status and Work Scope. 2- Detailed data of required materials per DWG./Isometrics after official approves for construction including Tag, Description, Qty.

Step by Step System

Identification of the goals and implementation of the work systems Run our web based software (Turboware) and share it with the points in the whole system which require information Recording all data related to materials and technical offices and data processing Providing online information and reports for software users Adding new reports or revising existing reports according to users feedbacks Facilitate the process of material delivery and data circulations in the whole system.

Usefulness of Aggregation

By having online data of available and required materials, MIV will be released by material management and technical offices after receiving MRC and compare them with their actual requirements while over MTO requests and NIS items will be dropped and just matched items with DWGs and available items in warehouse will be shifted in MIV formats. Different types of reports like material shortage and assignable materials for other projects from over materials can also be generated.

DWG./Isometrics Revision Followings

As there would be lots of changes and revisions in DWG./Isometric of construction projects, void items will be substituted by new revisions. Here materials which have been delivered to contractors according to the outdated revisions but are not required in new ones, will be identified and asked to be returned by MRV format to owner warehouse.

Check Isometrics, Piping Plans and PID, just by one click

As Built MTO on Hands

If there are authorized substitutions in materials of DWG./Isometrics, all changes will be recorded and can be submitted to engineering departments for any probable reconsiderations in supports and pipe rack calculations. For an instance, when pipes with higher wall thicknesses have been received at site, the actual delivered materials will be recorded and allocated for the erected Isometrics.

Feel Comfortable When Signing MTV

When owners define different construction projects with different warehouses, it maybe some items available in a warehouse which are shortage ones in another project. Here field engineers or construction managers of the owners can have controls about the status of items which have been requested through Material Transfer Vouchers by contractors from other projects.

Expiry Dates of Materials are Considered

Some materials in construction projects like Paints, Electrodes, Refractory Cement and etc. have limited qualification lifetimes. For these items, expiry dates of the materials together with their batch numbers will be entered and system automatically will put those Batches of the materials in summary formats which their expiry dates are more closed than the other batches.

Work Fronts Based on Owners Policies

Turboware System can provide the opportunity of allocating materials based on owners policies. For example while contractors will seek to perform the high volume lines and owner policy is to get the project to more possible tests, available materials will be assigned prior to complete the loops than the contractors requests.

Test packages become so friendly

Allocation of Materials Due to Contractors Working Range

This service will help owners when they use different contractors in a construction area. By defining the working ranges of each contractor in the system, just related materials of each range will be allocated to incumbent contractor.

Detailed Report

This report illustrates a clear history for each material (Tag) which includes Dates of Receipt, MRS Numbers, OPI Numbers, Total Received Quantities, Dates of Issue, MIV Numbers, Issued Quantities, Recipient Contractors, Total Issued Quantities, Required Quantity, Warehouse Inventory and MTO Balance.

Inventory Update and DWG./Isometrics Locking

As Materials will be delivered to contractors, qty of delivered items will be reflected on MIV documents. Warehouse returns the MIV documents to material management and technical offices management centre and by entering the MIV data in the system we will have: 1- Inventory of warehouse will be updated. 2- The DWG./Isometrics which their materials have been allocated through MIVs, will be locked by the system and system will prevent it to request more materials for them again to prevent material shortage due to making duplicate spools by contractors. 3- Software users can access to online warehouse inventory, materials which have been allocated to each DWG./Isometric and materials which have delivered to each contractor.

Support Brake down is not a headache any more